PET BOARD(无主图)

| Product Name | YOTOP PET Board/ HPL Board |

| Size | 1220x2440mm,1200*2400mm or customized |

| Thickness | 2-25mm |

| Thickness Tolerance | +/-0.3~0.5mm |

| Face/Back | PET film/ HPL laminated |

| Surface Treatment | Matt, textured or glossy |

| HPL Color | Solid color/wood grain |

| HPL Thickness | 0.5~1mm |

| Core | OSB/MDF/Particleboard/Plywood |

| Glue | WBP |

| Grade | A grade |

| Delivery Time | Within 20 days after receiving deposit or original L/C at sight |

| Certification | SO9001:2000, CE, CARB |

| Technical Parameters | Moisture Content:10%~15% |

| Water Absorption:≤10% | |

| Modulus of Elasticity:≥5000Mpa | |

| Static Bending Strength:≥30Mpa | |

| Surface Bonding Strength:≥1.60Mpa | |

| Internal Bonding Strength:≥0.90Mpa | |

| Screw Holding Ability:Face ≥1900N,Edge≥1200N |

1) What is PET?

Before explaining the PET board, let me tell you what is PET material. PET is the resin plastic of polyethylene terephthalate, in our daily life.Mineral water bottle, plastic wrap Or edible oil packaging bottles, plastic boxes, etc. All are applied PET materials. This PET material is both safe and environmentally friendly and it's not toxic. No toxic and harmful substances or gases will be produced reaching food-grade safety standards

What is PET board?

PET board, not to say that this board made of PET material. The most important thing is the PET film on the surface of the board substrate. So we usually say PET sheet. It's not actually a plank. It is a PET film with a thickness of 0.35-0.6mm.The thickness of the membrane skin is imported thinner.Domestic is thicker.

There are many kinds of base materials for boards. Such as OSB board, MDF board, Particleboard, Plywood, etc.Among them, this density board is the best choice as the base material. Because it is made into the base material of PET board. It is the best flatness among all the boards pass the base material and PET film through extrusion and bonding treatment of cold pressing equipment. Finally, the very popular PET board on the market is formed and often used for cabinet door panels.

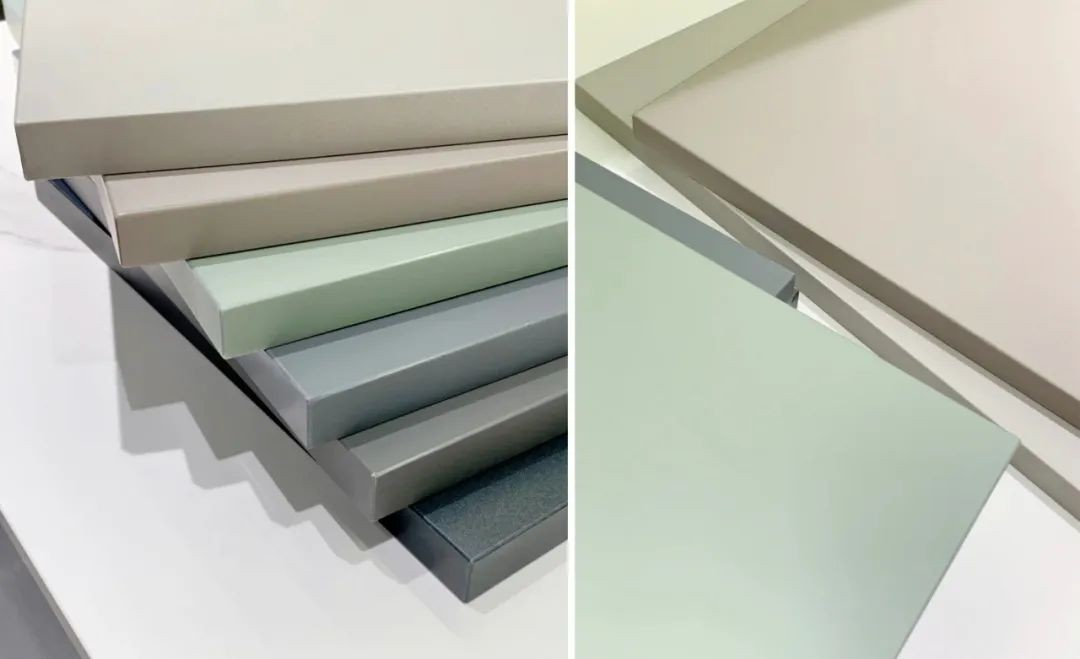

Type of PET board

PET sheet according to the degree of surface brightness can be divided into two types. One is glossy and the other is matte.

Glossy PET cabinet door panel

matte side here also commonly referred to as skin feel Or anti-fingerprint, skin feel, as the name suggests. Just touch the board with your hands.It feels like touching a baby's skin, smooth and delicate texture.

Matte skin-feeling PET cabinet door panel

The so-called anti-fingerprint means that we usually touch the cabinet door will leave obvious fingerprints on the cabinet door affecting the appearance. But the PET film in a very short time making fingerprints disappear instantly. Therefore in the market, this skin-feeling anti-fingerprint matte finish more popular than glossy surfaces.

Matte skin-feeling PET cabinet door panel

02.Advantages and disadvantages of PET board

1) Advantages of PET board

01. Good looking

02. High environmental protection and safety

03. Stable performance in all aspects

04. Smooth, delicate and comfortable touch